Many readers were surprised to learn the footwear industry uses 3D design. They assumed it was mainly for animated films. Here were a couple comments I received:

“Love the article! Do most companies make CG shoes? Do they use it for commercials or their website or something else?”

“Loving the shoe! Is that for an animated film? Is there a character coming soon?”

So this week, I want to dig a little deeper and explain why the footwear industry is leaning more toward 3D workflows, what tools and workflows they use, and what the future of 3D visualization is in the footwear industry. This is also piggybacking off my “3D for Dummies” Series I started with 3D Apparel for Dummies:

Why Do Footwear Designers Use 3D?

Transitioning from 2D to 3D design streamlines the footwear creation process and saves time and resources.

In the past, footwear designers relied on 2D designs and physical prototypes. They sketched ideas, manufactured first samples, and went through multiple rounds of physical revisions. This process was time-consuming, labor-intensive, and wasteful.

For example, shipping prototypes from Asian factories to US designers can be brutally long. They are often shipped on large container ships and that can take weeks or months. With physical prototyping, there is a huge lag between design approval and receiving a prototype.

With 3D design, brands skip many of these lengthy physical prototyping steps. Designers can review 3D models digitally and approve designs faster. Any issues with translating a 2D sketch to a 3D product are more easily resolved by revolving a 3D modle on screen.

Rather than wait for physical versions, brands can approve 3D designs and go directly to production samples. This saves significant time and shipping costs.

Then, if adjustments are needed after the production samples, the 3D model can be quickly adjusted to match and now the brand has a digital replica of the final product. These can immediately be used to create renders for marketing the new design and companies no longer have to wait for physical products and schedule photo studios to capture marketing images.

Beyond time-savings, 3D prototyping dramatically reduces environmental impact. Shipping and creating numerous physical samples consumes significant resources. Digital prototyping provides the same design feedback with a fraction of the waste and carbon footprint.

In summary, 3D design streamlines the early stages of footwear creation. It saves time, money, and environmental resources compared to traditional physical prototyping methods. The ability to digitally model, tweak, and approve designs is a game-changer for the footwear industry.

How are Footwear Designers using 3D?

There are fantastic 3D modeling tools that quickly allow footwear designers to begin to craft the form of the shoe they envision. This can be done in CAD software like Rhino, traditional 3D modeling tools like Blender, Maya, or ZBrush, or in new VR-based modeling applications like Gravity Sketch or Substance 3D Modeler.

The model could then be taken into software like Substance 3D Painter to add all the microdetail and material files to all surfaces.

Designers can craft precise shoe forms and add realistic material textures and colors in software like Substance Painter. This allows the creation and modification of designs digitally rather than waiting for physical prototypes.

This painted model can also be 3D printed to give the designers a better sense of the final product. Although the 3D printed materials differ from the final shoe fabrics, designers can evaluate overall shape and proportions.

The models also help with communication with the manufacturing centers. The 3D model can be rendered from various angles to communicate the design better than limited 2D sketches. The model provides factories with more complete design information than traditional orthographic drawings.

Finally, approved 3D assets can be brought into programs like Maya, Unreal, C4D, and After Effects. This allows generating product visuals and marketing content, from static images to animated sequences.

What’s are some unique struggles of footwear designers working in 3D?

To translate 3D shoe concepts into quality physical products, brands must nail details like scale and materials.

The 3D model dimensions must precisely match the final shoe size. Materials must replicate real-world colors, textures, and properties. The design vision fails if digital materials don't match what factories can produce.

Footwear companies rely on Color, Material, and Finish (CMF) designers to ensure this linkage. CMF designers select, specify, and source all colors, fabrics, trims, and surface finishes for products.

They forecast color/material trends, research innovative textures and fabrics, and curate CMF palettes that bring seasonal brand visions to life. CMF designers construct material libraries of leathers, textiles, hardware, etc. for designers to sample from.

CMF designers ensure 3D concepts translate to manufacturable products, among other fun tasks. Their expertise in materials, processes, and sourcing bridges the digital design world with physical production capabilities. For those interested in colors, textures, and building material libraries, CMF could provide a perfect fit for your skillset.

What’s next for 3D is footwear?

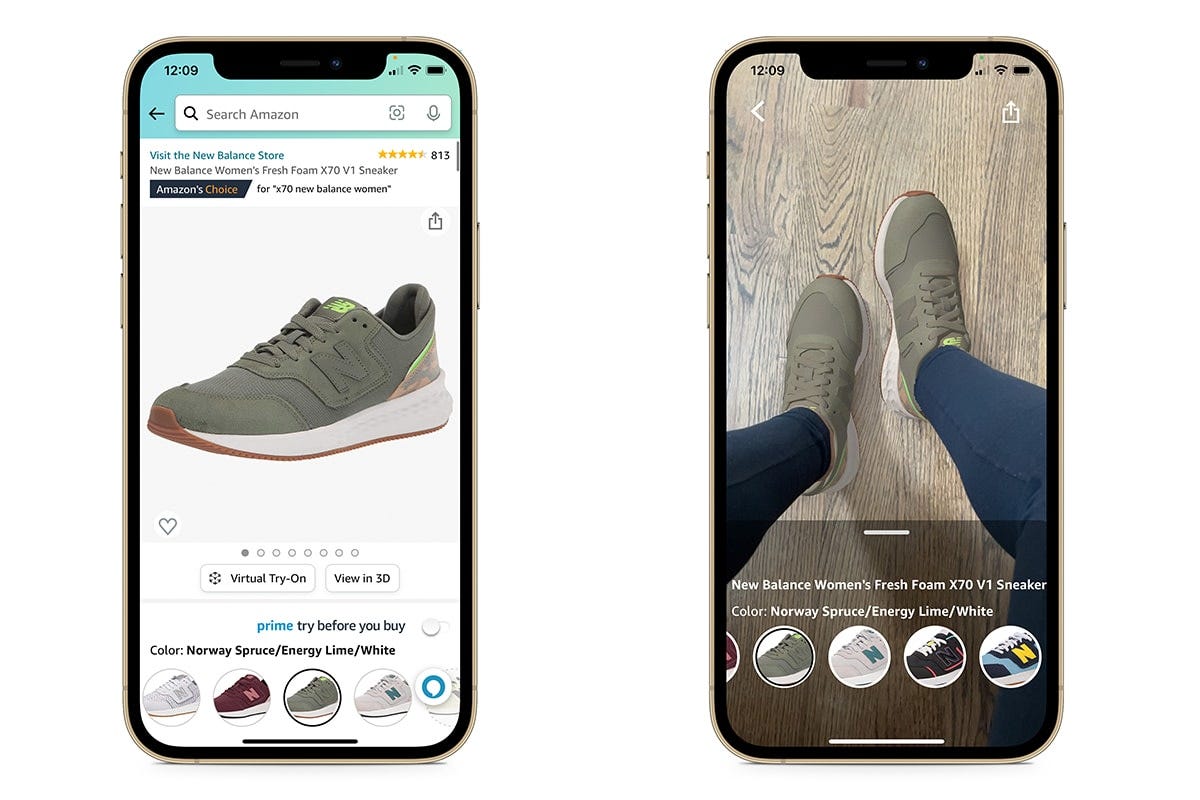

After design and marketing, mastering digital shopping experiences and virtual try-ons is critical for the future of footwear brands.

Virtual try-on allows online shoppers to visualize products on themselves digitally. For example, scanning a QR code could overlay 3D shoes onto your own feet via mobile phone.

This solves a major pain point - uncertainty about fit and appearance that leads to costly returns. Research shows interactive 3D experiences boost consumer confidence and lower returns significantly.

For footwear brands, returns are hugely expensive logistically. Virtual try-on minimizes waste and expense from dissatisfied customers sending items back.

It also provides a more engaging, customized shopping experience. Rather than rely on static photos, shoppers can interact with personalized 3D product visuals.

Virtual try-on technology bridges the digital and physical worlds. It gives shoppers more confidence in purchasing decisions while reducing returns for brands. As consumer expectations evolve, it will likely become a must-have digital experience rather than a nice-to-have.

Conclusion

The footwear industry’s adoption of 3D design has delivered huge benefits, with more to come.

So far, it has accelerated design cycles, reduced waste, and trending toward new possibilities like virtual try-on. But this is just the start.

As 3D technology improves, it will empower further personalization and sustainability. Brands can offer customized products tailored to individual consumers with less manufacturing waste.

Virtual design also enables easier experimentation with novel, eco-friendly materials and production methods before committing to physical samples. The future of footwear is undeniably digital. 3D unlocks speed, agility, and creativity difficult with traditional analog processes.

In summary, 3D is transforming footwear design and retail for the better. It delivers customer value while reducing environmental impact. The digitization of the footwear industry improves how brands bring inspired products to market and delight consumers.

3D News of the Week

In A Huge Win For VFX Workers, DNEG Vancouver Employees Have Won A Union - Cartoon Brew

This Cinema 4D Asset Library Is Now Available For Everyone - 80.lv

Netflix Cuts One-Third Of Feature Animation Division As Part Of Strategic Overhaul - Cartoon Brew

Adobe researchers create 3D models from 2D images ‘within 5 seconds’ in new AI breakthrough - Venture Beat

AI Will Cut Cost of Animated Films by 90%, Jeff Katzenberg Says - Yahoo Finance

3D Merch is here!

Click here to Get Your 3D Artist Swag!

Artist of the Week

3D Tutorials

3D Job Spreadsheet

Link to Google Doc With A TON of Jobs in Animation (not operated by me)

Michael Tanzillo is the Head of Technical Artists with the Substance 3D Growth team at Adobe. Previously, I was a Senior Artist on animated films at Blue Sky Studios/Disney with credits including three Ice Age movies, two Rios, Peanuts, Ferdinand, Spies in Disguise, and Epic.

In addition to his work as an artist, Michael is the Co-Author of the book Lighting for Animation: The Visual Art of Storytelling and the Co-Founder of The Academy of Animated Art, an online school that has helped hundreds of artists around the world begin careers in Animation, Visual Effects, and Digital Imaging.

www.michaeltanzillo.com

Free 3D Tutorials on the Michael Tanzillo YouTube Channel

Thanks for reading The 3D Artist! Subscribe for free to receive new posts and support my work. All views and opinions are my own!